|

|

NASH recommends Rotary type Nut Feeders for Square Nuts M12 & above Features

• Vibratory Feeders suitable for Square, Hexagon, Collared and T Nuts |

|

|

|

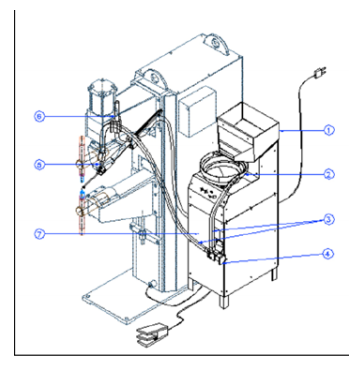

Automatic Vibratory Nut Feeders

NASH AVF 510

|

|

NASH recommends Rotary type Nut Feeders for Square Nuts M12 & above Features

• Vibratory Feeders suitable for Square, Hexagon, Collared and T Nuts |

|

|

|

Ceramic Pins  Projection Welding Electrodes

Automatic Nut Detection Facility Under Weld Head before Weld Initiation |

|