1

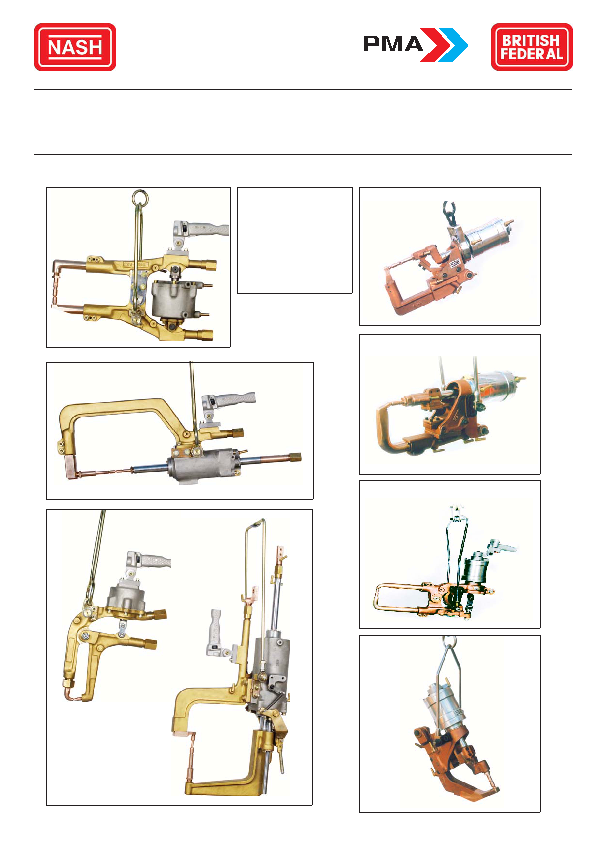

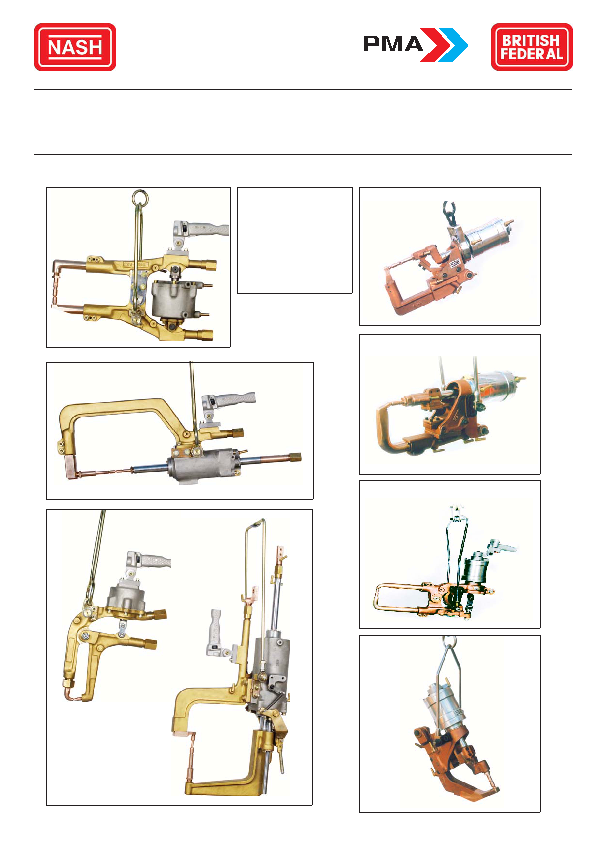

Non-IT Guns (Berryllium Copper/BsBu)

Copyright © 2003 Nash Infotech India All rights reserved Site best viewed with 800X600 screen setting and above |

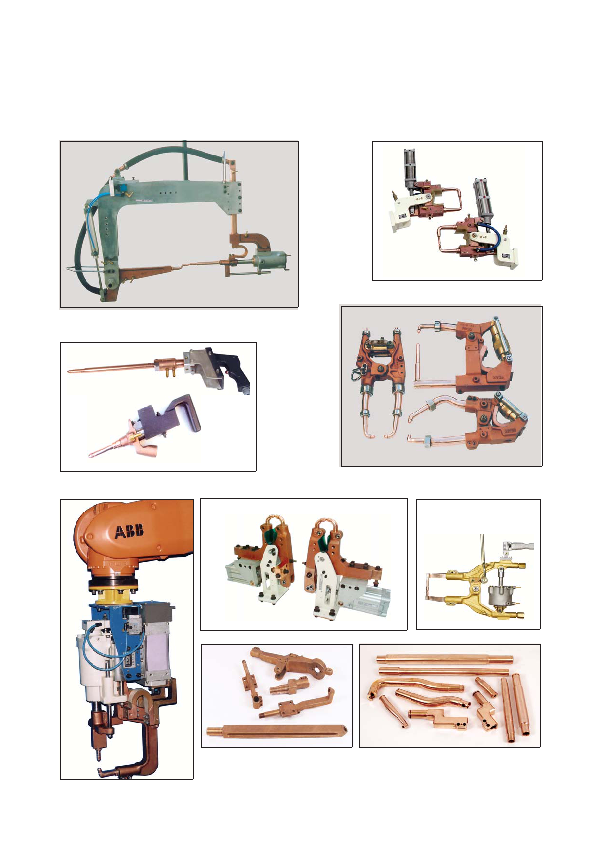

he design and manufacturing of precision welding guns apart from being

complex is highly technical. Process requires

unique consolidation of engineering fields. Keeping the most demanding needs for automotive and industrial fields

SEAM -

NASH group has established most modern manufacturing facilities involving

Mechanical, Metallurgical, Electrical

and Electronic Engineering disciplines.

SEAM - NASH has its own most modern non-ferrous foundry where each and every Gun arm is processed under strict

quality checks. Every SEAM - NASH Guns casting is internally cooled with water tubes which extend through the entire

length of

current path. These water tubes are cast in place and are accessible from both

sides of Gun.

TD 250

TG 95

Single Point Guns

Self Equalising (Auto) Gun

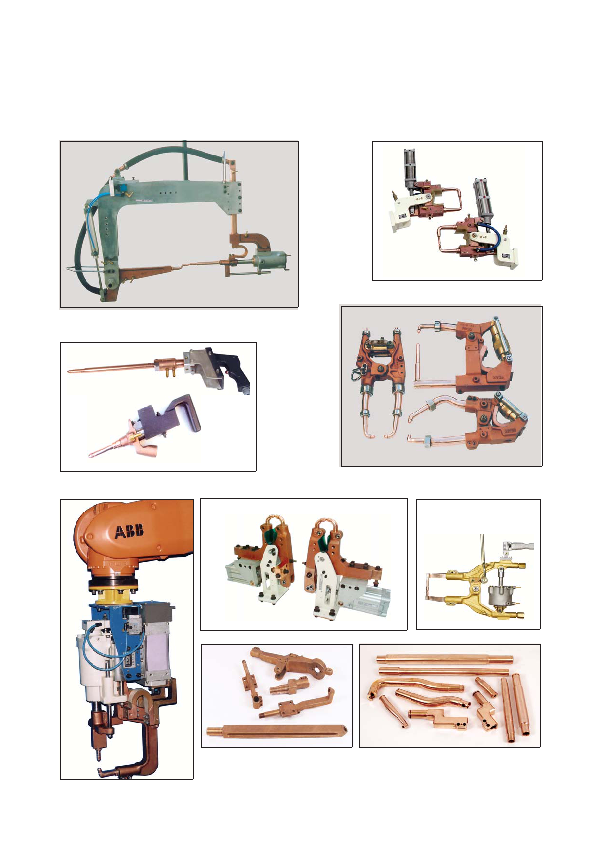

Cast Gun Arms

Class 3 Alloy, Be Cu

Round Gun Arms

Class 3 Alloy, Be Cu

Hydro-Pneumatic Guns

Robot Gun AC, Servo MFDC